View Mobile Number

Tooling Solutions

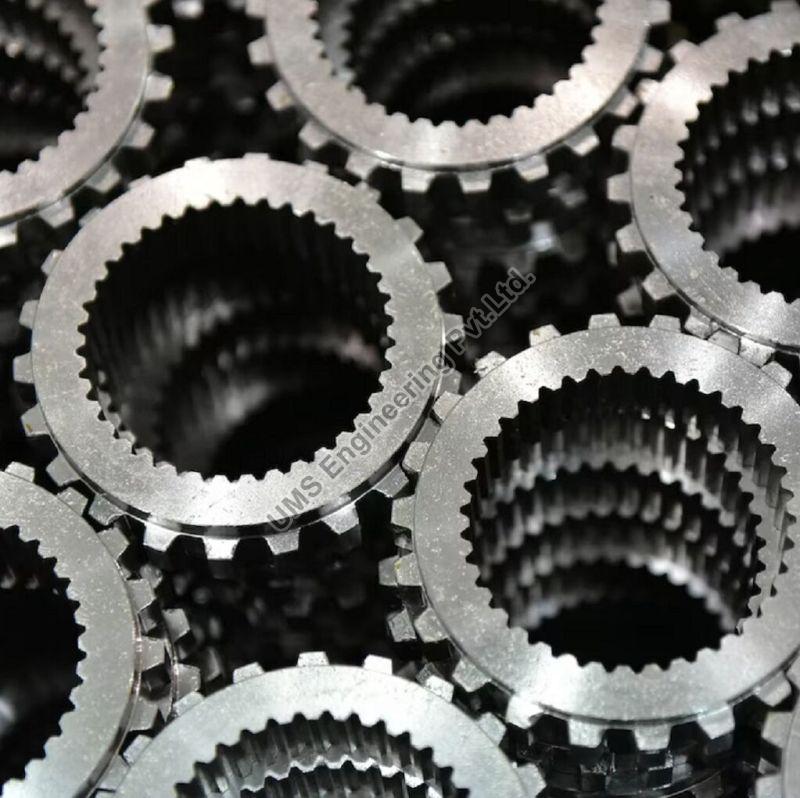

Leading Manufacturers, Exporters, Wholesaler of Press Tooling, Jigs and Fixtures Welding Services and Plastic Molding Services from Mumbai.

Our engineering website provides insights and guidance on progressive press tooling, an efficient manufacturing technique for complex metal parts with speed and precision, from design to troubleshooting.

Achievement:

- Developed a more efficient design for progressive press tooling.

- High customer satisfaction due to high-quality parts delivery.

- Implemented innovative process improvements to increase production capacity.

- Provided training and education to clients resulting in increased productivity.

- Industry awards and recognition for innovation, quality and customer service.

UMS understand the jigs and fixtures as your production tools used to accurately manufacture duplicate and interchangeable parts. UMS jigs and fixtures are specially designed so that large numbers of components can be machined or assembled. It help in the machining of jobs and reduce the human efforts required for producing parts & components. Types of fixtures UMS works on are Turning, Milling, Broaching, Grinding, Boring, Tapping, Duplex & Welding Fixtures. Different objects require different treatments like drilling, milling, planing, grinding machines, etc. Specific tools are necessary for producing these objects in identical shapes and sizes on a mass scale by holding and locating tasks to minimize the repetition work.

- Special Jigs & Fixtures

- Customized Jigs & Fixtures

- Innovative Jigs & Fixtures

- Wielding for Jigs & Fixtures

Molding is used to give desired shape to plastic and synthetic materials using different molding processes and is extremely popular method of manufacturing plastic parts and components for all kinds of applications. We understand the importance of the plastic part / component in their respective industry and hence choosing the right materials for the job is the most crucial step of the plastic injection moulding process cycle. We use Polythene, Poly-carbonate, Acrylic, Polyamide, Polystyrene, Polypropylene (PP), Acrylonitrile Butadiene Styrene (ABS) and Polyester materials.

- Thermo Plastic

- Thermo Set

- Rubber