View Mobile Number

1000 Piece (MOQ)

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Color | Silver & Golden |

| Usage | Used In Prototype And Manufacturing Assemblies |

| Click to view more | |

Product Details

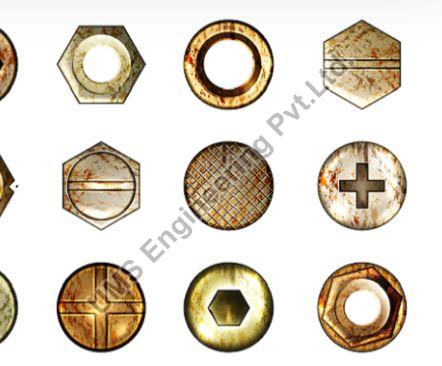

Riveting is a mechanical fastener, it is one of the major types of permanent material joining process used in prototype and manufacturing assemblies. Rivets are a strong and effective way to make permanent fastening of plates of light metal. Rivets are more capable and preferred for supporting shear loads rather than tension loads.

Raw Material

- The raw materials we use are of various International Standards like DIN, BS, ASTM, EN, JIS, ISI, etc for ferrous & non-ferrous metals.

- Non-Ferrous Metals like Copper, Brass & Other Copper Alloys, Aluminum (Aluminium) Alloys

- Ferrous Metals like Carbon Steels Alloy Steels Stainless Steels

- Hard Materials like Plastics & Polymers Phenolic Materials Fiber Glass

- Input Forms Utilized: Bar Stocks (Rounds, Squares, Flats & Profiles), Tubes & Pipes, Blocks & Thick Sections, Forgings & Castings

Supplementary Process

- As a part of our total solutions approach, we offer auxiliary and allied processes encompassing

- Heat Treatments: Conventional Hardening and Tempering / Annealing, Case Carburizing / Hardening, Induction Hardening, Plasma Nitriding et

- Surface Finishing: Polishing, Buffing, Etching, Laser Etching and Electro Polishing

- Surface Plating / Coatings: Zinc Plating, Nickel Plating, Black oxidizing, Powder Coating & anodizing in different Qualities / Colors etc

- Specialty Surface Plating / Coatings: Hard Chrome Plating, Silver & Tin Plating, Electrolysis Nickel, etc

Quality

All our products are manufactured in adherence to our quality policy & work system manuals. Please visit our quality page & work manuals for an in depth understanding of our procedures & systems. Additionally, quality procedures specific to our precision machined components manufacturing are… Typical testing & inspections inclusive of raw material testing for chemical composition and physical properties, surface roughness testing, ultrasonic testing, dye penetrant testing, etc as per clients’ drawing / specification Customized & comprehensive quality tests are as per client drawings / specifications using precisely designed and developed inspection gauges and devices

Policy

- We are committed to understanding our customers’ requirements in order to provide them with suitable, high-quality solutions. Our products and solutions are designed to help our customers succeed in the market.

- We believe the key contributors to customer delight and quality product are the employees, right processes & procedures, right machines, tools & equipment and management participation.

- Our team of expert specify the steps, phases and actions required to perform the process. Our Management team ensures right team and experienced people are selected for an assignment. The team lead is responsible for giving the working instructions & procedures to be followed, The worker knows, what is required to do be done in his everyday tasks. We nurture people of quality by continuous education and training. We explain them the importance of the parts or the component produced.

- Employees are provided with the right machines, tools & equipment to support quality product delivery.

- We continuously strive towards process improvement. Our quality policy sets out the framework for our quality objectives and is regularly reviewed to makes sure that it is still adequate and fit for purpose.

Looking for "Rivet Fasteners" ?

Explore More Products